Sanitary Vessel

Key words:

Pharmaceutical Engineering

Classification:

Detailed introduction

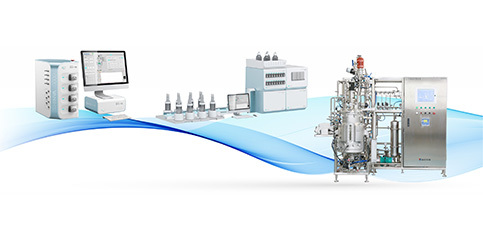

High standard sanitary vessel

Supply 5L-100,000L high standard sanitary vessels and accessories of different specifications

Fully support CIP/SIP, meet cleaning validation;

stainless steel S31603,S30408,duplex stainless steel S22053,titanium

Use low-temperature vacuum insulation technology, easy maintenance. Light weight, low thermal conductivity, good effect & stable performance

Insulation materials are non-toxic, odorless, nonflammable; has sound absorption performance. Insulation layer passed air tightness test, has a safe mouth breathing, safe and reliable

Vessel type

Reactor 、Preparation tank 、Culture tank 、Storage tank、Liquid preparation tank 、Inactivation tank 、Thawing plasma tank、PW/WFI tank、Mobile tank、Special material tank

Water cutting

Original imported water knife precision opening,The cut is regular and group pairs perfect.No heat affected zone to avoid oxidation

Welding

1、Professional automatic welding, 100% lossless

2、NDT, vibration after molding

3、Aging Technology (VSR) eliminates stress

Short section manhole

Specially-made short section manhole, no cleaning dead

Enhanced trumpet-shaped nozzle / NA interface

Self-processing enhanced trumpet-shaped nozzle / NA interface

Guaranteed strength and easy cleaning

Insulation technology

Low temperature vacuum filling pearl sand insulation technology,Good insulation effect, stable performance and maintenance-free

Internal and external surface treatment

External surface blasting + electrolysis to be a matte texture, which is conducive to cleaning and maintenance, reducing light pollution.Inner surface machine throwing + electrolysis to be a mirror surface, Ra≤0.4μm, non-stick wall, no hanging material, easy to clean

Pickling passivation

The whole tank body is pickled and passivated to form a dense anti-oxidation layer.Increase equipment corrosion resistance

Recommended Products